Introduction

In the world of screen printing, quality matters. Whether you’re a small business owner or a seasoned professional, the ink you choose for your designs can make or break your finished product. Skip Marsh Plastisol Ink has established itself as a go-to solution for those seeking top-notch, durable prints. Known for its exceptional pigment, smooth application, and resilience, Skip Marsh Plastisol Ink offers a range of advantages that make it ideal for printing on textiles.

This guide will take you through everything you need to know about Skip Marsh Plastisol Ink, including its features, benefits, and how to use it effectively to achieve vibrant, long-lasting prints. If you’re looking to create high-quality custom apparel or other fabric products, Skip Marsh Plastisol Ink might just be the key to your success.

What is Skip Marsh Plastisol Ink?

Before diving into the details, let’s first understand what Skip Marsh Plastisol Ink is. This ink is a type of screen printing ink made from PVC resin suspended in plasticizers. Skip Marsh Plastisol Ink is ideal for use in textile printing, particularly for T-shirts, hoodies, and other fabric items.

Unlike water-based inks, which can be challenging to work with due to their tendency to dry quickly, Skip Marsh Plastisol Ink is oil-based, meaning it remains workable for longer periods. It’s known for its ability to produce rich, vibrant colors that stand the test of time, without cracking, fading, or peeling easily.

Whether you’re new to screen printing or have been in the business for years, Skip Marsh Plastisol Ink can help elevate your prints, producing professional-grade results every time.

Key Features of Skip Marsh Plastisol Ink

1. Vibrant and Bold Colors

When it comes to color vibrancy, Skip Marsh Plastisol Ink stands out. The ink is designed to deliver crisp, sharp, and vivid colors, which is essential for designs that need to pop, especially on dark fabrics. It’s ideal for printing bold logos, intricate patterns, or large-scale designs that require high color saturation.

Additionally, Skip Marsh Plastisol Ink provides excellent opacity, which is essential for printing on darker garments. Many other inks may struggle to show up clearly on dark colors, but Skip Marsh Plastisol Ink ensures that your designs stay visible and vibrant, even on black or navy blue shirts.

2. Long-Lasting Durability

One of the primary reasons for choosing Skip Marsh Plastisol Ink is its durability. Once cured, the prints remain intact for the long haul. Unlike water-based inks, which can fade or crack over time, Skip Marsh Plastisol Ink offers excellent resistance to wear and tear. This makes it a fantastic option for apparel that will be washed frequently, such as custom T-shirts, sportswear, or uniforms.

The ink also resists cracking or peeling, which can often be an issue with other types of ink, especially after numerous washes. This makes Skip Marsh Plastisol Ink an excellent choice for businesses selling long-lasting apparel or for anyone looking to make sure their custom designs stand the test of time.

3. Ease of Use

Another standout feature of Skip Marsh Plastisol Ink is how easy it is to use. Whether you are printing manually or using an automatic press, the ink has a consistency that makes it easy to apply. This makes it an excellent option for both novice screen printers and experienced professionals.

Because Skip Marsh Plastisol Ink does not dry out as quickly as water-based inks, it gives you more time to work with your design, allowing you to make necessary adjustments during the printing process without the ink setting prematurely. This feature is especially helpful when printing large quantities of apparel or working with complex designs.

4. Versatility Across Different Fabrics

Skip Marsh Plastisol Ink is incredibly versatile, making it suitable for a variety of fabric types, including cotton, polyester, and cotton-polyester blends. It works well with both light and dark-colored garments, which is crucial for printers who need to produce high-quality prints on different fabric materials.

Moreover, Skip Marsh Plastisol Ink can be used in a variety of printing methods, including manual and automatic screen printing presses. This makes it a flexible option for businesses of all sizes, whether you’re printing small batches of custom shirts or large orders for corporate clients.

5. Smooth Application and Excellent Coverage

The smooth texture of Skip Marsh Plastisol Ink ensures that it flows through the screen easily and creates an even layer on the fabric. This smooth application also helps you achieve clean, sharp edges in your design. Whether you’re working on fine details or larger areas, this ink ensures consistent coverage, making your prints look professional.

Additionally, Skip Marsh Plastisol Ink can cover a wide range of fabric colors and textures without losing its boldness, even when printed on challenging materials like textured fabrics.

How to Use Skip Marsh Plastisol Ink for Perfect Prints

1. Prepare the Screen

Before using Skip Marsh Plastisol Ink, it’s essential to ensure that your screen is properly prepped. This involves cleaning it thoroughly to remove any old ink or residue. If there is any debris or grease on the screen, it can affect the quality of your print, so make sure the screen is in pristine condition.

Check the screen tension, as well. For optimal results, you need the mesh to be properly stretched and taut. Test the screen with a small amount of ink to ensure it’s compatible and flows smoothly before starting your main print.

2. Mix the Ink

Skip Marsh Plastisol Ink is typically ready to use right out of the container. However, depending on your project, you may need to adjust the ink’s consistency. If the ink seems too thick for your design, you can add a plastisol reducer to thin it out. Be cautious when adding the reducer – just a small amount is enough, as too much can alter the color and quality of the print.

On the other hand, if you need a thicker consistency, you can add a thickening agent designed specifically for plastisol inks. Always mix thoroughly to achieve a uniform consistency.

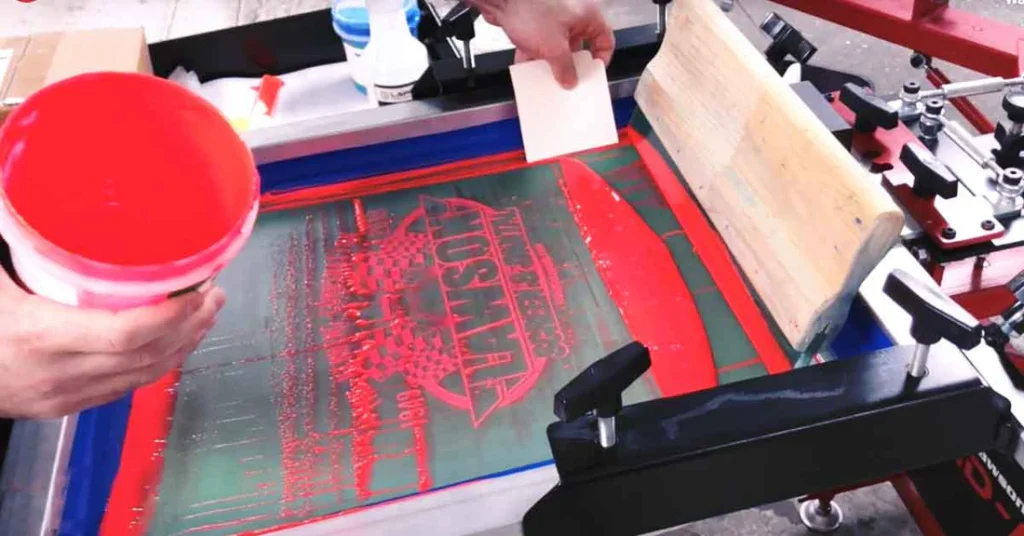

3. Printing Process

When it’s time to start printing, apply Skip Marsh Plastisol Ink to the screen. The amount of ink you use depends on the size and complexity of your design, but generally, you should have enough ink to cover the entire design area without overloading the screen.

Using your squeegee, press the ink through the screen and onto your fabric. The squeegee should be angled at around 45 degrees for optimal pressure. The key to smooth, crisp prints is consistent, even pressure, so be sure to apply steady pressure as you move the squeegee across the screen.

4. Curing the Ink

Once you’ve printed your design, the next step is curing. Skip Marsh Plastisol Ink requires heat to cure properly and bond to the fabric. Use a heat press or conveyor dryer set to the recommended temperature (usually between 320°F and 330°F) for 2-3 minutes. Make sure the ink is completely cured before handling or packaging the garment to ensure the print’s durability.

5. Post-Print Care

After curing, allow the garments to cool before folding or packaging them. Cooling ensures that the ink is fully set and will not smudge. It’s also important to store your printed garments properly to avoid any damage to the ink or fabric.

Common Questions About Skip Marsh Plastisol Ink

1. Is Skip Marsh Plastisol Ink eco-friendly?

While Skip Marsh Plastisol Ink is not water-based, it is considered safe when used correctly. The ink does not contain harmful solvents or chemicals, making it a safer alternative to some other types of inks. However, proper disposal and cleaning techniques should be followed to minimize environmental impact.

2. What fabrics can I print on with Skip Marsh Plastisol Ink?

Skip Marsh Plastisol Ink works on a variety of fabrics, including cotton, polyester, and cotton-poly blends. It’s versatile enough to handle a range of materials, making it a great choice for custom apparel manufacturers.

3. How long does a print last with Skip Marsh Plastisol Ink?

With proper curing, prints made with Skip Marsh Plastisol Ink can last for many years without fading, cracking, or peeling. The durability of the print is one of the main reasons why this ink is so highly regarded in the screen printing industry.

4. Can Skip Marsh Plastisol Ink be used with automatic printing presses?

Yes, Skip Marsh Plastisol Ink is highly compatible with both manual and automatic screen printing presses. It’s a popular choice among printers using automatic presses due to its consistency and ease of use.

Conclusion

To sum up, Skip Marsh Plastisol Ink offers a range of benefits that make it the preferred choice for screen printing on textiles. With vibrant colors, outstanding durability, and ease of use, this ink is perfect for both small-scale and large-scale printing projects. Whether you’re printing custom T-shirts, creating corporate apparel, or designing promotional products, Skip Marsh Plastisol Ink provides consistent, high-quality results that will stand the test of time.

By incorporating Skip Marsh Plastisol Ink into your printing workflow, you can enhance the overall quality of your prints, ensuring that your designs look great and last for years to come. So, if you’re ready to take your screen printing to the next level, give Skip Marsh Plastisol Ink a try and see the difference for yourself.